Performance Requirements of Electric Furnace Lining

Date:2016-07-01 18:06 From:Zhengzhou Sunrise Refractory Author:sunrise

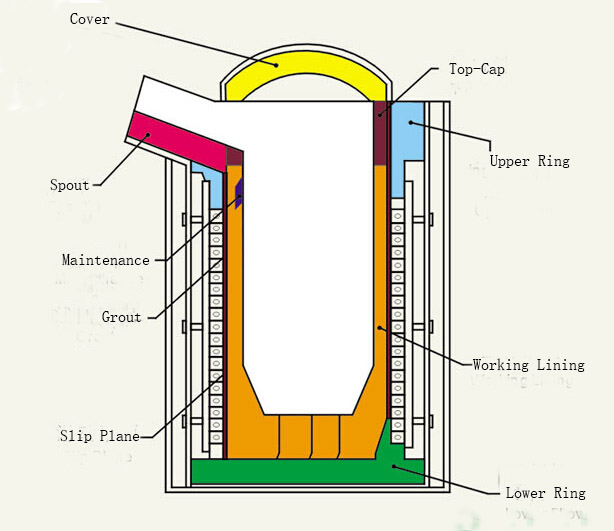

The electric furnace lining refers to the lining of the melting chamber, including the furnace cover, walls and the bottom. Its performance directly affects the quality of steel and other economic and technical indicators.

The refractory materials for the furnace lining include basic refractory and acid refractory. Currently, most electric furnaces adopt basic linings. The acid lining is only used in the production of steel castings or gray cast iron.

The requirements for the refractory materials of electric furnace lining include:

1) Have enough refractoriness and softening temperature under load. Under the action of the arc, the temperature of the inner surface in different parts can be up to 1500-1800℃.

2) Have high resistance to slags. The slag, smoke and dust at high temperature will permeate into its interior through the lining, which will cause the damage and spalling of refractory materials.

3) Have good thermal shock resistance. In the steelmaking process, the temperature of the lining materials may have sudden changes due to operations such as opening the door and lifting the furnace cover. Sometimes, spalling and cracks may occur.

4) Have enough strength. The lining may suffer from shock during loading, vibration during tilting and erosion by metal, molten slags and gas flow during boiling.

5) Have low thermal conductivity and electrical conductivity.

The main refractory materials used in the electric furnace include magnesia brick, dolomite brick, high alumina brick, silica brick and magnesia ramming mass. Since the working conditions in different parts are different, the refractory materials used are different.

Zhengzhou Sunrise Refractory Co., Ltd. is a refractory supplier from China, specializing in refractory materials for glass furnaces. Our main products are as follows: fused cast AZS 33#,36#,41#, glass furnace fireclay bottom block, mullite brick, zircon brick, alumina bubble brick, sillimanite brick, corundum brick, low porosity fireclay brick, high alumina brick, all kinds of glass furnace ramming masses, sealing materials, building fireclay, etc.

Send an Inquiry

E-mail : sales@sunriserefr.com

Phone : +86-371-63838939 / Fax:+86-371-63835539

Company Address : No.36 Fengchan Road Of Zhengzhou, Henan, China (Mainland)

If you have any needs our help or are interested in our products, you can click online advisorychat with us online, or call our customer service telephone: 0086-0371-63838939. We will sincerely serve for you!

Product Category

- Fused Cast AZS

- Fused Cast AZS Block

- Fused Cast Skid Rail Block

- Fused Cast High Zirconia Block

- Fused Cast AZS Block

- Fiber Products

- Insulation Series Brick

- Fireclay Brick

- High Alumina Brick

- Corundum Brick

- Sillimanite Brick

- Mullite Brick

- Zircon Mullite Brick

- Zircon Brick

- Magnesia Brick

- Silica Brick

- Fused Cast Alumina Block

- Glass Mould Brick

Refractory Knowledge

moreCase

UAE to our factory inspection bri

...

Venezuela customer AZS fused bric

Venezuela customer AZS fused float glass furnace br...