The Manufacturing Process Of Fused Cast AZS Block

Date:2016-05-17 17:59 From:Zhengzhou Sunrise Refractory Author:sunrise

Fused cast AZS block is the most widely used refractories in the glass industry. Its quality and performance is mainly up to its manufacturing process.

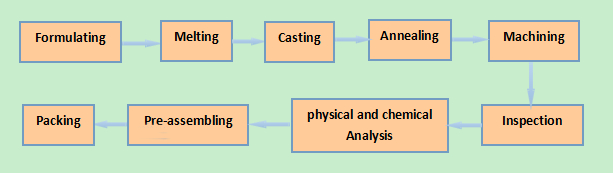

The manufacturing process of fused cast AZS block including formulating, melting, casting, annealing, machining, inspection, physical and chemical analysis, pre-assembling and packing.

Formulating

Weight the raw materials and mix them together based on the formulation.

Melting

Pour the raw materials in the automatic controlled electric arc furnace. When melting the glass in the single-phase or three-phase electric arc furnace, the temperature should be appropriate. It the temperature is low, it is difficult to obtain highly homogeneous glass melt, which will make the cast products porous and causes large shrinkage cavities and cracks. The key of the melting process is to keep the melting temperature steady to obtain melt with uniform chemical composition, low carbon content and good casting performance.

Casting

Pour the melt into the special designed molds to form AZS block with dense structure and good performance. Improving the temperature of melt can make the shrinkage cavities concentrated and the structure denser. But if the temperature is too high, through the density increases, the possibility to form cracks and large shrinkage cavities increases too.

Annealing

Cool the cast products slowly to make the crystals grow and form the best structure. Usually put the molds in insulation boxes filled with diatomite when annealing. The initial temperature of annealing and the insulation effect have great impact on the annealing performance.

Machining

Use precise processing equipment to process the AZS block to the precise dimension. Machining can also improve the quality and service life of AZS.

Inspection

According the quality standard and contract requirement, inspect each block strictly.

Physical and chemical analysis

According the quality standard and contract requirement, analyze the physical and chemical parameters of AZS.

Pre-assembling

Pre-assemble the block used in the demanding areas according to the drawing of furnaces.

Packing

Pack the block according to its properties and the general packing requirement of refractories.

Sunrise is a refractory material supplier from China. The main products of Sunrise include fused cast AZS block, fused cast alumina block, mullite brick, zircon brick, alumina bubble brick, sillimanite brick, corundum brick, low porosity fireclay brick, high alumina brick, all kinds of glass furnace ramming masses, etc..

Send an Inquiry

E-mail : sales@sunriserefr.com

Phone : +86-371-63838939 / Fax:+86-371-63835539

Company Address : No.36 Fengchan Road Of Zhengzhou, Henan, China (Mainland)

If you have any needs our help or are interested in our products, you can click online advisorychat with us online, or call our customer service telephone: 0086-0371-63838939. We will sincerely serve for you!

Product Category

- Fused Cast AZS

- Fused Cast AZS Block

- Fused Cast Skid Rail Block

- Fused Cast High Zirconia Block

- Fused Cast AZS Block

- Fiber Products

- Insulation Series Brick

- Fireclay Brick

- High Alumina Brick

- Corundum Brick

- Sillimanite Brick

- Mullite Brick

- Zircon Mullite Brick

- Zircon Brick

- Magnesia Brick

- Silica Brick

- Fused Cast Alumina Block

- Glass Mould Brick

Refractory Knowledge

moreCase

UAE to our factory inspection bri

...

Venezuela customer AZS fused bric

Venezuela customer AZS fused float glass furnace br...