The History And Development Of ZrO2-Containing Refractory

Date:2015-07-21 19:57 From:Zhengzhou Sunrise Refractory Author:sunrise

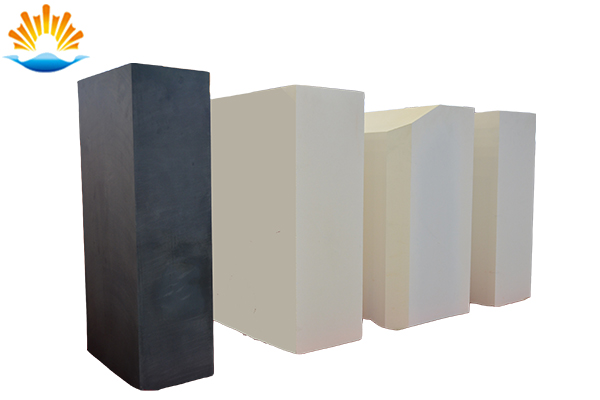

ZrO2 containing refractory is a kind of refractory made of Zirconia (ZrO2) or zircon (ZrSiO4). Zirconia refractories, zircon refractories, zircon mullite refractories and zircon corundum refractories belong to this kind of refractory.

Depending on the production method, ZrO2 containing refractories can be divided into sintered refractories, fused cast refractories and non-sintered refractories. They are featured with high melting point, low thermal conductivity, stable chemical property and good corrosion resistance to glass and metal liquid.

Since 1790s when the baddeleyite mineral was found, many scholars began to study zirconia and ZrO2 containing refractories also began to be produced and applied. In 1920, Corning produced the large cast mullite brick, and in 1923 it began to be used in the glass furnaces. In 1941, Corhart ZAC fused cast zirconia corundum brick began to be produced in USA and expanded the service life of glass furnaces to 2-4 times. In 1947, in order to improve thermal shock resistance, c.E.Curtis produced partially stable zirconia by adding CaO or MgO. In 1950, Norton produced cast stable zirconia in a single-phase electric arc furnace. In 1953, Asahi Glass (AGC) also began to produce the cast zirconia brick. In the late 1980s, the Soviet Union produced fused cast zirconia corundum brick with 50% and 60% ZrO2. In 1960, Sepr began to produce ZASl681 fused cast zirconia corundum brick. In 1965, fused cast AZS 33# began to be produced in China.

The main component of zircon is ZrSiO4 and at 1680℃, it will be decomposed into ZrO2 and SiO2. Zircon refractories have good corrosion resistance to metal liquid, acid reagent and glass liquid, but are easy to react with alkali slags. As fused cast AZS block and sintered AZS block have good corrosion resistance to glass liquid, they are used in the sidewall and superstructure of glass furnaces.

The main raw materials used to produce ZrO2 containing refractories include Baddeleyite, zircon and zirconia. The crystal phase of Baddeleyite is monoclinic crystals. The ZrO2 content of Baddeleyite varies according to its origin, from 80% to 95%. The main impurities include Fe2O3, TiO2, SiO2, Al2O3 and HfO2. The main crystal phase of Zircon is tetragonal crystal. The main impurities include ilmenite and monazite. Zirconia with the same chemical composition, according to its crystal phase, can be divided into Monoclinic zirconia, tetragonal zirconia and cubic zirconia. During the heating and cooling process, different crystal phases can suffer from reversible or irreversible crystal transformation. The crystal transformation is reversible and accompanied by 7% volume change, which causes thermal shock.

ZrO2 containing refractories have high refractoriness, high mechanical strength and good chemical stability. They are widely used in the metallurgy industry, constructing industry, chemical industry and machinery industry. For their good corrosion resistance to glass liquid, they are also widely used in the demanding areas of glass furnaces and have effectively improved the service life of glass furnaces and the quality of glass products.

Send an Inquiry

E-mail : sales@sunriserefr.com

Phone : +86-371-63838939 / Fax:+86-371-63835539

Company Address : No.36 Fengchan Road Of Zhengzhou, Henan, China (Mainland)

If you have any needs our help or are interested in our products, you can click online advisorychat with us online, or call our customer service telephone: 0086-0371-63838939. We will sincerely serve for you!

Product Category

- Fused Cast AZS

- Fused Cast AZS Block

- Fused Cast Skid Rail Block

- Fused Cast High Zirconia Block

- Fused Cast AZS Block

- Fiber Products

- Insulation Series Brick

- Fireclay Brick

- High Alumina Brick

- Corundum Brick

- Sillimanite Brick

- Mullite Brick

- Zircon Mullite Brick

- Zircon Brick

- Magnesia Brick

- Silica Brick

- Fused Cast Alumina Block

- Glass Mould Brick

Refractory Knowledge

moreCase

UAE to our factory inspection bri

...

Venezuela customer AZS fused bric

Venezuela customer AZS fused float glass furnace br...