The Use of Refractory Materials in the Regenerators of Glass Furnaces

Date:2015-12-09 21:07 From:Zhengzhou Sunrise Refractory Author:sunrise

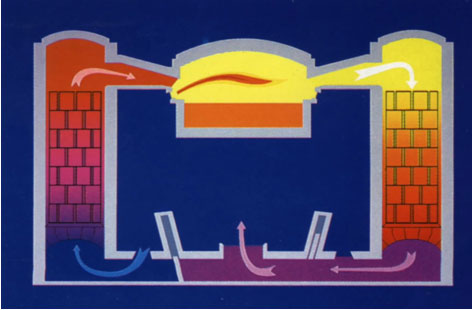

The regenerator is an important part of the large glass furnaces. It has a significant influence on the utilization rate of the exhaust heat and energy consumption.

The exhaust gas passes through the regenerator. A part of heat is transferred to the regenerator checkerwork. After the direction of the air flow is changed, the heat stored by the cheankerwork is transferred to the air.

The different parts have different working conditions and different requirements for the refractory materials. The upper checker bricks are mainly subjected to the corrosion by the high temperature alkali fly ash and alkali vapor, while the middle checker bricks are mainly damaged by the liquid - solid phase change of Glauber (Na2SO4) liquid in the bricks.

The regenerator is composed of the crown, the wall, checkerwork and rider arch.

1) The crown

The crown of the regenerator is built with high quality silica brick and then insulated with materials similar to those of the crown of the melting zone.

2) The wall

The walls including partition walls should have the same structure and material in the same horizontal section. The upper wall should be lined with high quality silica bricks and insulated with light weight fire clay insulation brick and insulation coating or calcium silicate board. The upper target wall can be built with directly bonded magnesia chrome brick and insulated with high alumina insulation brick and insulation coating or calcium silicate board. The part of the wall from the rider arch to the checkerwork top should use the same materials to the checker bricks at the same height. In the upper and middle part of the wall, bricks with a lower grade than the checker brick at the same height can be used. In the lower part of the wall, low porosity fire clay brick can be used. The wall should be insulated and sealed with fire clay insulation brick or high alumina brick, insulation coating or calcium silicate board.

3) The checkerwork

There are generally two types of checker bricks: cross-shaped fused cast AZS checker bricks and basic checker bricks. The former has a longer service life (more than 10 years), but it is expansive. Although service life of the later is not as long as that of the fused cast AZS, it has a low cost and, therefore, has a wider application.

The matching program of the basic bricks is as follows:

1400-1200 ℃ temperature zone: High pure magnesia brick 97 and 95 with great resistance to chemical attack;

1200-1100 ℃ temperature zone: Magnesia brick 92 with great corrosion resistance;

1100-800 ℃ temperature zone: Direct bonded magnesia chrome brick and spinel brick with great resistance to the phase change of Glauber;

800℃ below temperature zone: Low porosity fire clay brick.

When the basic lath brick is used as the checker brick, since it has bad thermal stability, every brick cannot be overhung when stacking. Every brick should be completely supported by the following brick and sufficient expansion joints should be reserved. When fueled with heavy oil or high calorific value gaseous fuel, the regenerator only preheats the combustion air.

In furnaces of the daily glass, the low calorific value gaseous fuel should be preheated by the gas regenerator. Magnesia chrome bricks with high iron content are not suitable to the gas regenerator with cyclical changes in the atmosphere, since the change of atmosphere can cause the valence change of the iron and damage to the bricks.

In the boron glass furnaces, the basic brick should not be used in the regenerator, because the basic brick can absorb B2O3 at high temperature, which reduces its strength.

4) Rider arch

If the checkerwork is built with sintered refractories, the rider arch and leveling brick should be built with high-strength low-porosity fire clay brick. If the checkerwork is built with cross-shaped fused cast AZS bricks, the rider arch and leveling brick should be built with fused cast AZS and a layer of fire clay arch should be added to protect the rider arch.

Send an Inquiry

E-mail : sales@sunriserefr.com

Phone : +86-371-63838939 / Fax:+86-371-63835539

Company Address : No.36 Fengchan Road Of Zhengzhou, Henan, China (Mainland)

If you have any needs our help or are interested in our products, you can click online advisorychat with us online, or call our customer service telephone: 0086-0371-63838939. We will sincerely serve for you!

Product Category

- Fused Cast AZS

- Fused Cast AZS Block

- Fused Cast Skid Rail Block

- Fused Cast High Zirconia Block

- Fused Cast AZS Block

- Fiber Products

- Insulation Series Brick

- Fireclay Brick

- High Alumina Brick

- Corundum Brick

- Sillimanite Brick

- Mullite Brick

- Zircon Mullite Brick

- Zircon Brick

- Magnesia Brick

- Silica Brick

- Fused Cast Alumina Block

- Glass Mould Brick

Refractory Knowledge

moreCase

UAE to our factory inspection bri

...

Venezuela customer AZS fused bric

Venezuela customer AZS fused float glass furnace br...