Corrosion And Refractory Selection For The Throat Of The Glass Furnace

Date:2016-05-17 18:10 From:Zhengzhou Sunrise Refractory Author:sunrise

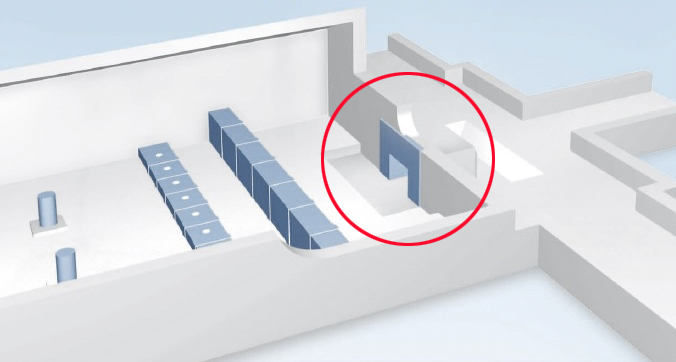

The throat is one of the important parts in the glass furnaces. All glass liquid flows through the throat into the work end. It is used in almost all glass furnaces to improve the quality of glass.

In the melting process, since the unmelted sand and dross have lower density, they are suspended in the upper layer of the glass liquid. The throat can prevent the unmelted sand and dross into the work end and sort the glass liquid.

The throat can increase the use area of the melting zone and improve the melting capacity of the furnace. It can also reduce or avoid the reflux of glass liquid from the cooling zone to melting zone. It can also reduce the temperature of the glass liquid. By adjusting its location, size and cooling degree, the temperature can be adjusted.

The flowing speed in the throat is the biggest and the convection is serious, thus the throat bricks, especially the cover tiles, are subjected to severe wear and corrosion. Under the cover tiles is glass liquid. Bubbles cause vertical undercutting corrosion. Therefore, cover tiles are easily damaged and one of the weakest points of the furnaces. Fused cast AZS 41# WS is used here. In borosilicate glass furnaces, fused silica brick is used.

Fused cast AZS 41# WS has compact microstructure and low blistering potential. Since the better corrosion resistance to molten glass. Since the shrinkage cavity part is cut, it has best corrosion resistance to molten glass among the AZS blocks.

Zhengzhou Sunrise is a refractory material supplier from China, offering high quality refractory materials for glass furnaces, including fused cast AZS block, fused cast alumina block, fused cast high zirconia block, mullite brick, zircon brick, alumina bubble brick, magnesia brick, sillimanite brick, corundum brick, low porosity fireclay brick, high alumina brick, all kinds of glass furnace ramming masses, etc..

Send an Inquiry

E-mail : sales@sunriserefr.com

Phone : +86-371-63838939 / Fax:+86-371-63835539

Company Address : No.36 Fengchan Road Of Zhengzhou, Henan, China (Mainland)

If you have any needs our help or are interested in our products, you can click online advisorychat with us online, or call our customer service telephone: 0086-0371-63838939. We will sincerely serve for you!

Product Category

- Fused Cast AZS

- Fused Cast AZS Block

- Fused Cast Skid Rail Block

- Fused Cast High Zirconia Block

- Fused Cast AZS Block

- Fiber Products

- Insulation Series Brick

- Fireclay Brick

- High Alumina Brick

- Corundum Brick

- Sillimanite Brick

- Mullite Brick

- Zircon Mullite Brick

- Zircon Brick

- Magnesia Brick

- Silica Brick

- Fused Cast Alumina Block

- Glass Mould Brick

Refractory Knowledge

moreCase

UAE to our factory inspection bri

...

Venezuela customer AZS fused bric

Venezuela customer AZS fused float glass furnace br...