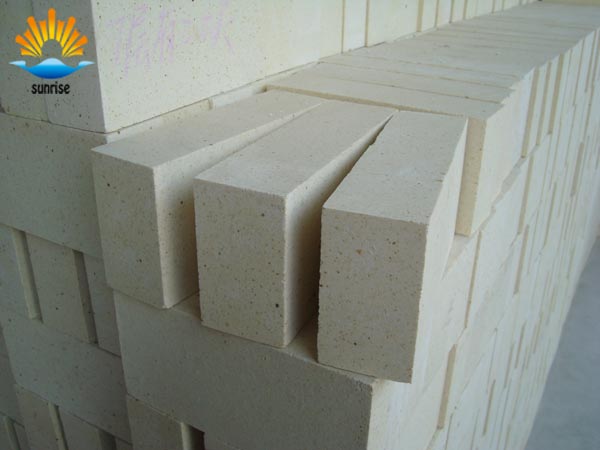

Types And Applications Of Insulation Bricks

Date:2016-05-17 18:06 From:Zhengzhou Sunrise Refractory Author:sunrise

Insulation bricks are high porosity refractories with low thermal conductivity used in order to reduce the rate of heat flow (heat losses) and thus to maximize heat conservation within the furnace.

The desirable feature of insulation bricks is the low thermal conductivity, which usually results from a high degree of porosity. Insulating materials can be classified with respect to chemical composition:

Fire Clay Insulation Brick

It is a type of insulation material for industrial furnaces to reduce heat loss, save energy and reduce the load of the equipment. It is made of local top grade fireclay materials. It possesses even bulk density, high strength, low thermal conductivity and low impurity. It is mainly used for the insulating lining of hot surfaces or backing heat-insulating layers of other refractory materials.

Silica Insulation Brick

It is mainly made of top class silica, via shaping and burning under the high temperature, possesses high temperature resistant, high strength and low impurities, etc. Its thermal conductivity is only half of that of the dense silica brick. It has good thermal insulation effect, good acid erosion resistance, high softening point. It has no shrink at high temperature, thus it has better thermal shock resistance than fire lay insulation brick. The main applications are the low temperature parts such as blast furnaces and hot blast furnaces, waste incinerators and glass melting furnaces.

High Alumina Insulating Brick

It is a new type of lightweight insulating material which contains approximately 48% alumina. It has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

Mullite Insulation Brick

It is mainly made from good quality and pure raw materials.In generally, alumina accounts 65%-75%. Besides mullite,there are also glass phase and christobalite as well as corundum which are good grade fillings. It has low thermal conductivity and high strength and can contact with flame directly. It is popular in hot blast kiln crown, glass melting furnace regenerator,ceramic sintering kiln,Petroleum cracking system corners and linings,ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etc.

Diatomite Insulation Brick

It is made of high diatomite, bonding with other porous materials. Produced by our licensed technology, shaping by casting, sintering at high temperature then cutting and polishing to the demand sizes, the strength and insulating property are obviously improved. It can be used in reduction cell and hot blast pipe of various thermal equipment, which placed in the high requirement on heat-insulating.

Zhengzhou Sunrise is a refractory material supplier from China, offering high quality refractory materials for glass furnaces, including fused cast AZS block, fused cast alumina block, fused cast high zirconia block, mullite brick, zircon brick, alumina bubble brick, magnesia brick, sillimanite brick, corundum brick, low porosity fireclay brick, high alumina brick, all kinds of glass furnace ramming masses, etc..

Send an Inquiry

E-mail : sales@sunriserefr.com

Phone : +86-371-63838939 / Fax:+86-371-63835539

Company Address : No.36 Fengchan Road Of Zhengzhou, Henan, China (Mainland)

If you have any needs our help or are interested in our products, you can click online advisorychat with us online, or call our customer service telephone: 0086-0371-63838939. We will sincerely serve for you!

Product Category

- Fused Cast AZS

- Fused Cast AZS Block

- Fused Cast Skid Rail Block

- Fused Cast High Zirconia Block

- Fused Cast AZS Block

- Fiber Products

- Insulation Series Brick

- Fireclay Brick

- High Alumina Brick

- Corundum Brick

- Sillimanite Brick

- Mullite Brick

- Zircon Mullite Brick

- Zircon Brick

- Magnesia Brick

- Silica Brick

- Fused Cast Alumina Block

- Glass Mould Brick

Refractory Knowledge

moreCase

UAE to our factory inspection bri

...

Venezuela customer AZS fused bric

Venezuela customer AZS fused float glass furnace br...